Impact of Implementing Smart Systems in Manufacturing & Production Facilities

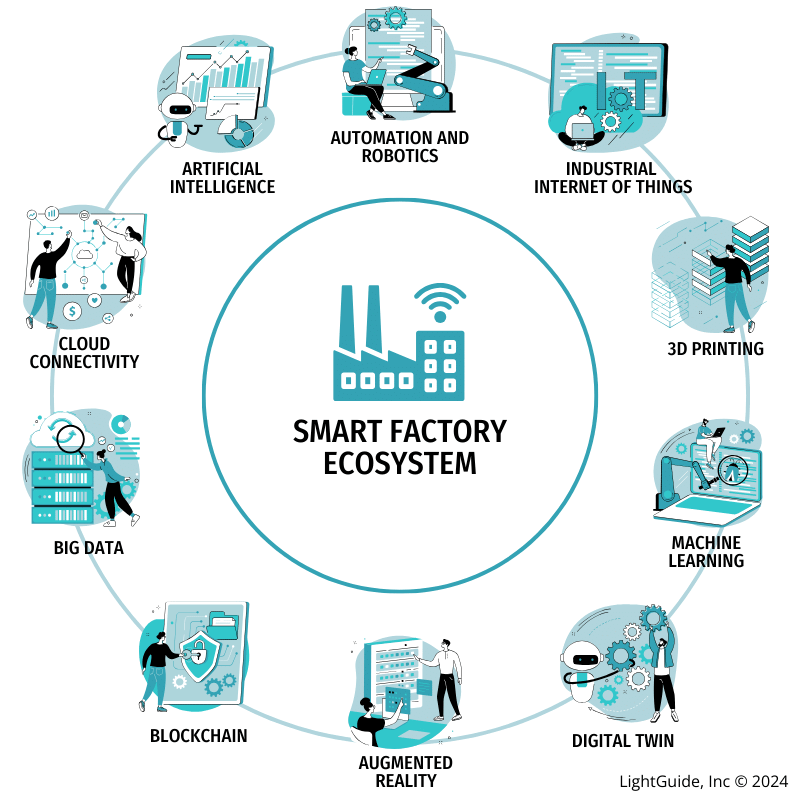

In the era of Industry 4.0, the integration of smart systems within manufacturing and production facilities is revolutionizing operations. These systems, powered by advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics, are enhancing efficiency, product quality, and flexibility. A critical component underpinning these advancements is the infrastructure of specialized cables, including Building Management System (BMS) cables, control cables, and instrumentation cables, which ensure seamless connectivity and data transmission.

Enhancing Operational Efficiency

Implementing smart systems leads to enhanced operational efficiency by enabling real-time monitoring and control of production processes. IoT sensors and data analytics facilitate the identification of bottlenecks, predictive maintenance to prevent downtime, and optimization of resource usage. For instance, predictive maintenance systems analyze machinery performance to schedule repairs proactively, significantly reducing unplanned downtime. Specialized cables from DigitalStout play a pivotal role in this context, providing the high-performance BMS and control cables necessary for reliable connectivity across facilities.

Improving Product Quality

Quality assurance is another area where smart systems make a substantial impact. Technologies like machine vision and AI detect defects early in the production line, ensuring consistent product quality, reduced waste, and enhanced customer satisfaction. The precise functioning of sensors and automated equipment in these systems relies heavily on specialized cables. DigitalStout offers instrumentation and control cables that are essential for maintaining high standards in quality assurance processes.

Flexibility and Scalability in Operations

The flexibility and scalability of production processes are greatly improved through smart systems. AI-driven automation and robotics allow facilities to adapt quickly to changing market demands, switch between product lines, and scale operations efficiently. This adaptability is supported by robust cabling solutions from DigitalStout, designed to handle high-speed data and power requirements, ensuring the scalability of smart systems.

Enhancing Safety and Sustainability

Worker safety and environmental sustainability are also enhanced through the implementation of smart systems. These systems monitor workplace conditions, reduce energy consumption through optimized operations, and minimize waste and emissions via precise process controls. DigitalStout contributes to these goals by providing durable and high-performance cables, including fire-retardant BMS cables and low-smoke halogen-free options, aligning with modern safety and sustainability standards.

Data-Driven Decision-Making

Data-driven decision-making is at the core of smart manufacturing. By collecting and analyzing vast amounts of information, smart systems empower decision-makers to identify trends, make informed strategic decisions, and enhance overall business performance. The accuracy and speed of these insights depend on reliable data transmission, supported by DigitalStout's specialized cables.

Optimizing Supply Chain Management

The impact of smart systems extends beyond the production floor to the entire supply chain. Enhanced inventory management, better coordination between suppliers and manufacturers, and improved delivery accuracy are facilitated by smart technologies. DigitalStout's instrumentation cables ensure the uninterrupted flow of data and power across various touchpoints in the supply chain, supporting overall efficiency.

Addressing Implementation Challenges

While the benefits of smart systems are substantial, their implementation presents challenges, including high initial investment costs, integration complexities with legacy systems, and cybersecurity risks. However, with proper planning and the right technology partners, these challenges can be effectively addressed. Partnering with DigitalStout for specialized cabling needs ensures that smart systems are built on a reliable and future-proof foundation.

Conclusion

The implementation of smart systems in manufacturing and production facilities is essential for maintaining competitiveness in today's market. By enhancing efficiency, improving product quality, and enabling data-driven decision-making, these systems are shaping the future of the industry. DigitalStout is proud to play a pivotal role in this transformation by providing top-quality BMS, control, and specialized cables that power these innovative solutions. Manufacturers who embrace these advancements today will lead the way in the smart industrial revolution of tomorrow.

For inquiries or to learn more about how Digital Stout can support your Building Management System needs, reach out to us today!

Email: sales@digitalstout.com

Contact: Mohammed Salman Mirza, Manager

Phone: +971 50 669 8540

We're here to help you build smarter and more efficient solutions!